Ultrasonic Spraying PCB

Ultrasonic spraying equipment: opening a new chapter of efficient and precise spraying in the PCB industry

In the electronic manufacturing industry, the quality of printed circuit boards (PCBs) directly affects the performance and reliability of electronic products. With the rapid development of electronic technology, the manufacturing process of PCBs is constantly being optimized and upgraded. Ultrasonic spraying equipment, as a new type of spraying technology, is gradually becoming the preferred solution for efficient and precise spraying in the PCB industry.

1. Overview of Ultrasonic Spraying Technology

Ultrasonic spraying technology is a technique that uses ultrasonic vibration to atomize liquid coatings and achieves uniform spraying through precise control. Ultrasonic spraying equipment mainly consists of ultrasonic generator, nozzle, control system and other parts. During operation, the high-frequency vibration generated by the ultrasonic generator is transmitted to the nozzle, causing the paint to produce small droplets as it passes through the nozzle, thereby achieving a uniform and fine coating.

2. The advantages of ultrasonic spraying equipment in the PCB industry

- Uniform spraying and stable quality

Ultrasonic spraying equipment can achieve efficient atomization of coatings, and the sprayed coating is uniform and consistent, avoiding common problems such as dripping and accumulation in traditional spraying methods, and improving the quality stability of PCBs. - Fine control and strong adaptability

Ultrasonic spraying equipment can accurately control the spraying amount of paint, adapt to PCB boards of different thicknesses and materials, and meet the spraying needs of various complex patterns and micro circuits. - Improve the utilization rate of coatings and reduce costs

Due to the excellent atomization effect of ultrasonic spraying on coatings, the utilization rate of coatings is high, reducing coating waste and lowering production costs. - Environmental protection and energy conservation, reducing pollution

Ultrasonic spraying equipment reduces the amount of paint used, lowers VOC emissions, and is beneficial for environmental protection. At the same time, the equipment operates with low noise, improving the working environment.

3. Application of Ultrasonic Coating Equipment in PCB Industry

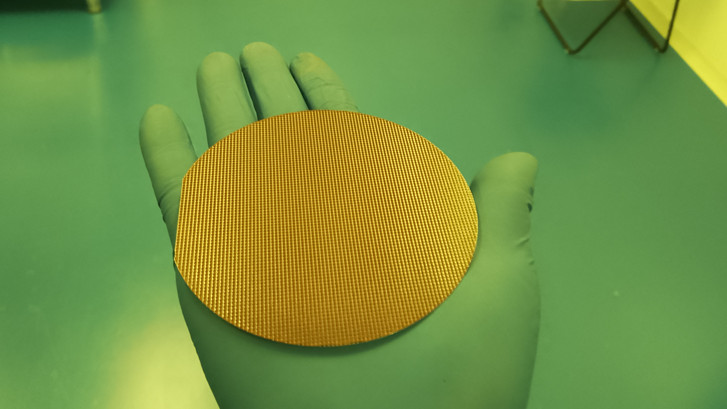

- Copper laying process

In the copper plating process of PCB, ultrasonic spraying equipment can accurately and uniformly spray conductive coating on the surface of the circuit board, forming a conductive layer and providing a good foundation for subsequent electroplating or chemical plating. - Solder mask spraying

The solder mask layer is an important protective layer on the PCB, and ultrasonic spraying equipment can ensure that the solder mask is evenly covered on the circuit board, forming a dense protective film to prevent solder joints from short circuiting. - Character printing

The character printing on PCB requires clarity and accuracy. Ultrasonic spraying equipment can achieve precise character spraying, ensuring long-term readability of the identification.

The emergence of ultrasonic spraying equipment provides an efficient, precise, and environmentally friendly spraying solution for the PCB industry. With the continuous maturity and application promotion of technology, ultrasonic spraying technology will further enhance the overall level of PCB manufacturing and promote the development of the electronics industry. In the future, we have reason to believe that ultrasonic spraying equipment will play a greater role in PCB manufacturing and even broader fields, contributing to the transformation and upgrading of China’s electronic manufacturing industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions