Spray Coating of Electrolytic Water Electrolyzer

Proton exchange membrane electrolysis of water for hydrogen production is a device that decomposes water into hydrogen and oxygen by applying external electrical energy. In this process, the proton exchange membrane plays a crucial role, allowing only protons (hydrogen ions) to pass through, thereby achieving the generation of hydrogen gas at the cathode and oxygen gas at the anode.

With the increasing demand for clean energy, proton exchange membrane electrolysis of water for hydrogen production has received widespread attention as an efficient and clean method of hydrogen production. The performance of the electrolyzer directly affects the efficiency, cost, and quality of hydrogen production, so its optimization is crucial.

Ultrasonic spraying machine uses the energy of ultrasonic waves to atomize liquid spraying materials into extremely fine and uniform droplets. This atomization effect is achieved through the high-frequency vibration generated by ultrasound in the liquid, resulting in the formation of small peaks and valleys on the surface of the liquid, ultimately forming uniform droplets. It can precisely control the size, velocity, and spray direction of droplets. This characteristic is particularly important for the spraying of proton exchange membrane electrolysis water to hydrogen electrolysis cells, as the internal structure of the electrolysis cell is complex and requires precise application of spraying materials to specific areas.

The application advantages of ultrasonic spraying machine in electrolyzer spraying

1. Coating uniformity guarantee

– Uniform coating is crucial for improving electrolysis efficiency and extending the lifespan of proton exchange membrane electrolysis water hydrogen electrolysis cells. The uniform droplets formed by the ultrasonic spraying machine can form a coating with consistent thickness on the surface of the electrolyzer, ensuring the uniformity of coating quality on both the electrode surface and the wall of the electrolytic cell.

2. Protecting proton exchange membranes

– The performance and lifespan of proton exchange membranes are key factors in hydrogen production through water electrolysis using proton exchange membranes. By using an ultrasonic sprayer, protective coatings can be sprayed around the proton exchange membrane or related components to prevent impurities, corrosive substances, and other damage to the proton exchange membrane, thereby improving its stability and service life.

3. Improve electrode performance

– The precise spraying characteristics of ultrasonic spraying machines can ensure the quality of electrode surface coatings when spraying specific catalytic or protective materials on the electrode surface. Appropriate coatings can enhance the catalytic activity of electrodes, reduce overpotential, and thus improve the efficiency of hydrogen production through electrolysis of water.

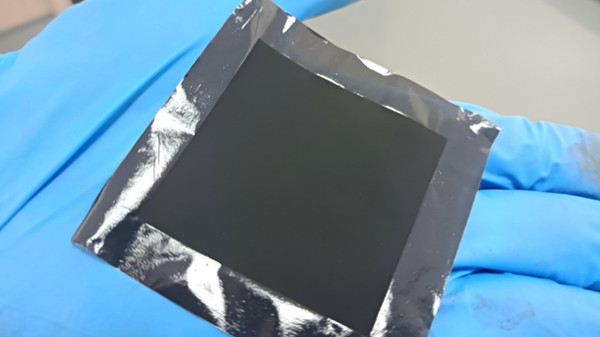

The operational process in practical applications

1. Pre treatment of electrolyzer

-Before spraying, it is necessary to thoroughly clean and pretreat the proton exchange membrane electrolysis water hydrogen electrolysis cell. To remove impurities such as oil stains, dust, and possible oxides from the surface, in order to ensure good adhesion between the sprayed material and the surface of the electrolyzer.

2. Selection of spraying materials

-Select appropriate spraying materials based on the specific requirements of the electrolyzer. For example, if it is to improve the catalytic performance of the electrode, spraying materials containing highly active catalysts may be selected; If it is to improve corrosion resistance, corrosion-resistant ceramic or polymer materials will be chosen.

3. Parameter setting and spraying

-According to the structure, size, and characteristics of the spraying material of the electrolyzer, set the parameters of the ultrasonic spraying machine, such as ultrasonic frequency, spraying speed, and the distance between the nozzle and the surface of the electrolytic cell. Then proceed with the spraying operation, paying close attention to the uniformity and thickness of the spraying process.

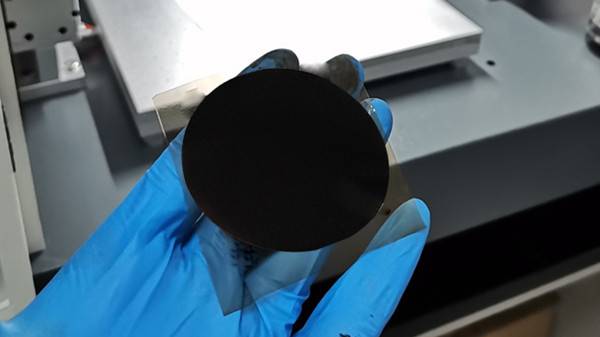

4. Quality inspection

-After the spraying is completed, it is necessary to inspect the spraying quality of the electrolyzer. The testing content includes the thickness, uniformity, adhesion, and impact on the performance of the electrolyzer of the coating. Through various testing methods such as optical microscopy observation and electrochemical performance testing, ensure that the spraying quality meets the requirements.

Development prospects

1. Improve hydrogen production efficiency and stability

-With the continuous development of technology, ultrasonic spraying machines are expected to play a greater role in the optimization of proton exchange membrane electrolysis water to hydrogen electrolysis cells. By continuously improving the coating quality, the efficiency of hydrogen production and the stability of electrolyzer operation can be further enhanced, reducing the cost of hydrogen production.

2. Promote the development of the hydrogen energy industry

-Against the backdrop of the booming global hydrogen energy industry, the application of ultrasonic spraying machines in proton exchange membrane electrolysis water to hydrogen electrolysis cells can help enhance the competitiveness of the entire hydrogen energy industry chain. The optimization of hydrogen production equipment and the improvement of hydrogen quality will lay a solid foundation for the widespread application of hydrogen energy in the energy field.

The ultrasonic spraying machine has unique advantages in the spraying application of proton exchange membrane electrolysis water to hydrogen electrolysis cells, and has broad development prospects, which is of great significance for promoting the development of the hydrogen energy industry.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions