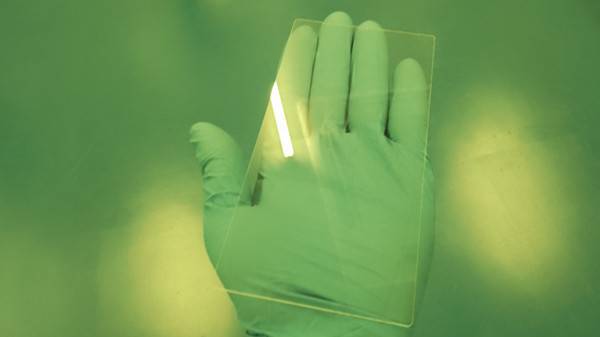

Ultrasonic Photoresist Coating Equipment for Coating Glass

In the fields of modern optics and microelectronics, glass, as an important material, often needs to be coated with photoresist on its surface to achieve various precision processing and manufacturing purposes. The emergence of ultrasonic coating equipment has brought new technological means and advantages to the coating of photoresist on glass.

Advantages of coating photoresist on glass

1. Coating uniformity

- Uniformity is crucial for coating photoresist on glass surfaces. The small and uniform droplets formed by ultrasonic coating equipment can form a very uniform photoresist coating when applied to the surface of glass. This can provide a stable and consistent foundation for subsequent photolithography processes such as exposure and development, ensuring the manufacture of high-precision optical or microelectronic components.

2. Improve adhesion

- The vibration of ultrasonic waves can to some extent clean the tiny impurities on the surface of glass and better bond the photoresist molecules with the glass surface. This better bonding force helps to improve the adhesion of photoresist on glass and reduce the risk of photoresist detachment during subsequent processing.

3. Accurately control the coating thickness

- By adjusting the parameters of the ultrasonic coating equipment, such as ultrasonic frequency, power, coating time, etc., the coating thickness of photoresist on glass can be accurately controlled. This is very advantageous for situations where there are strict requirements for photoresist thickness in different application scenarios, such as in the manufacturing of high-precision optical lenses or microelectronic chips.

Application

1. Manufacturing of optical components

- In the manufacturing of optical components such as optical lenses and filters, uniformly coating photoresist on glass is the first step to achieve precise optical pattern production. Ultrasonic coating equipment can meet the strict requirements for photoresist coating in high-quality optical component manufacturing, which helps to improve the performance of optical components, such as the accuracy of transmittance and refractive index distribution.

2. Microelectronics manufacturing

- In the manufacturing of microelectronic chips, the coating of photoresist on glass substrates is an important step in the photolithography process. Uniform and precise thickness control of photoresist coating is crucial for the fabrication of micro circuit patterns on chips. The application of ultrasonic coating equipment can improve the accuracy and reliability of microelectronic manufacturing, helping to produce smaller and higher performance chips.

Ultrasonic coating equipment has many advantages in coating photoresist on glass, including improving coating uniformity, adhesion, and precise control of coating thickness. It has broad application prospects in fields such as optical component manufacturing and microelectronics manufacturing. With the continuous development of technology, it is expected to play an important role in more related fields.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions