Benefits of Ultrasonic Nano Spraying System for 3D Bioprinting

Benefits of Ultrasonic Nano Spraying System for 3D Bioprinting – Cheersonic

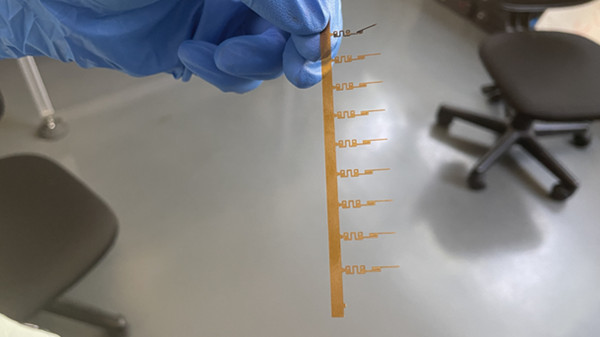

Ultrasonic nano coating spray systems for bio 3D printing are advanced technologies that enhance the surface properties of 3D-printed biological structures. These systems utilize ultrasonic spraying to apply ultra-thin, uniform coatings of biomaterials or protective substances, offering several benefits:

1. Uniform Coating: The ultrasonic mist allows for even distribution of coatings on complex geometries, ensuring comprehensive coverage of bio-printed constructs.

2. Enhanced Biocompatibility: Coatings can be tailored with biocompatible materials, improving integration with biological tissues and reducing the risk of rejection.

3. Controlled Morphology: The coating process can be finely tuned to achieve specific surface characteristics, such as hydrophilicity, porosity, and roughness, which are crucial for cell attachment and growth.

4. Minimized Material Waste: Ultrasonic spraying is efficient, reducing excess material use and lowering production costs in bio 3D printing applications.

5. Improved Mechanical Properties: Coatings can enhance the mechanical strength and durability of bio-printed structures, making them more suitable for various medical applications.

6. Drug Delivery Capability: Coatings can incorporate therapeutic agents, enabling controlled drug release directly from the bio-printed scaffolds.

In summary, integrating ultrasonic nano coating spray systems into bio 3D printing enhances the functionality, biocompatibility, and performance of printed constructs, paving the way for advancements in tissue engineering and regenerative medicine.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions