Hemostatic Sponge Automatic Ultrasonic Cutter

We specialize in providing customized solutions to meet the needs of emerging cutting-edge industries such as nanotechnology, fuel cells, semiconductors, medical, spray pyrolysis, and more.

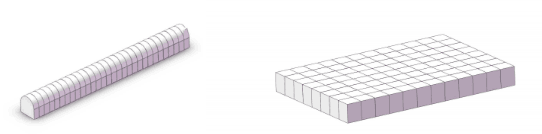

UFM6000 is a high-efficiency ultrasonic cutting equipment with fully automatic and multi-functional features. The cutting efficiency of hemostatic sponges can be applied to the cutting of hemostatic sponges in rectangle, strip and other shapes to achieve the ideal cutting effect. The product to be cut is placed in the ultrasonic automatic cutting equipment, and the equipment will position and cut the cutting product according to the parameters input in advance, and automatically complete the operation without human intervention, thereby improving work efficiency. Ultrasonic vibration reduces the frictional resistance between the blade and the hemostatic sponge, so that the blade can cut the hemostatic sponge smoothly without deformation, and there will be no burning of the cut surface. Ultrasonic vibration reduces material sticking on the blade, thereby reducing downtime in cleaner production systems. Throughout the cutting process, the blade surface remains smooth, clear and clean.

- Output: 60-200 hemostatic sponges can be cut per hour

- The cut surface is smooth and beautiful without burning

- Fully automatic product positioning, multi-functional and all-round cutting according to demand

- The cutting products can be automatically positioned and cut according to the parameters entered in advance

- Fully automatic use of ultrasonic for efficient slitting, saving manpower

Features and Parameters

Feature

• All stainless construction

• Precise positioning, multi-stage variable speed, adjustable slitting speed

• Titanium alloy with optional tool

• Self-developed multi-axis control system

• Fully automatic development of multi-axis control systems

• Has a friendly human-machine interface

• Self-contained infrared sensor protection device to ensure operator safety

• Automatic frequency tracking, real-time tracking of ultrasonic cutter frequency

• 3 system permissions – Operator, Supervisor and Technician

Basic Parameters

• Size: 1000*1400*1860mm

• Voltage: 220V 50-60 Hz 10A

• Power: 2.5Kw

• Effective cutting height 80mm (60/150mm)

• Effective cutting width: 305mm

• Number of cutting knives: 2

• Control: 7-inch human-computer interface (independently developed by Cheersonic)

• Product input and output: manual loading

• Certificate: CE, FDA

OUR EXPERTISES

Cheersonic offers innovative and customized solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your production.

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China